Enamel Steel Panel

Panacor PPP: Passive Protective Panel with Vitreous Enamel Steel

Enamel steel is a type of steel that has been coated with an enamel layer. Enamel is a glass-like Material that goes through a high-temperature firing process. This specific coating protects the steel from corrosion, staining, and scratching, while also enhancing the material’s aesthetic appeal and functionality. The combination of steel’s mechanical strength and enamel’s durability makes it a versatile material for various applications.

What Are The Steps Of The Enamelling Process?

- Firing coats of enamel on steel.

- Panel formation and shaping.

- Panel degreasing and rinsing.

- Applying the ground-coat enamel.

- Firing the enamel (820°C-850°C).

- Applying the enamel finishing coat.

Where Can Enamel Be Applied?

Enamelled steel can be used for both interior and exterior architectural projects and new or renovated buildings, as well as civil engineering projects, including:

- Roofing.

- Cladding.

- Tunnels.

- Partitions.

- Decoration.

Factory general view

PANACOR PPP, Advanced Prefabricated Vitreous Enamel Steel Panels

PANACOR PPP is a high-performance steel panel system designed with vitreous enamel coating. This finish is applied through a static powder enamelling technique, which involves firing the panels at temperatures above 800°C. The result is an extremely durable coating, fused on both sides of the steel, creating a highly resistant surface that bonds permanently to the metal.

Known for its exceptional toughness, the vitreous enamel layer protects against graffiti, abrasion, and impact, making PANACOR PPP an ideal choice for busy public spaces like train stations and ground-level facades, where durability is critical.

Each panel is made from heavy-duty, cold-rolled, decarbonized steel that complies with UNE‐EN 14431 and EN 10209 standards. The steel undergoes a specialized high-temperature treatment, ensuring superior adhesion of the coating and long-lasting performance. Panels include at least two layers of enamel on the exterior and one on the interior for maximum protection.

PANACOR PPP panels are delivered as prefabricated cassettes and can be tailored into various shapes, including curved configurations to suit specific design needs. With a wide selection of color options, they offer architects and designers significant creative flexibility. Their long service lifespan and low maintenance requirements also make them a highly economical choice.

Whether you’re building resilient public infrastructure or seeking a bold architectural solution, PANACOR PPP delivers enduring strength, visual appeal, and reliable performance.

Our vitreous enamelled steel panels offer outstanding performance, making them one of the most durable architectural cladding materials available. They are resistant to rust, chemical corrosion, abrasion, and fire, which outperforms traditional cladding in both resilience and longevity.

Highly versatile, these panels can be customized to suit virtually any design, regardless of shape and size. As well as support the integration of graphics, logos, and an extensive spectrum of colours. Their robust finish ensures they maintain their original color and aesthetic appearance throughout the typical lifespan of a building, even in harsh environments.

Whether exposed to extreme conditions or coastal environments, vitreous enamelled panels require low maintenance and cleaning while delivering consistent performance and visual appeal over time.

The PANACOR PPP Vitreous Steel Panels Benefits Include:

- HIGH REFLECTANCE AND LUMINOSITY:

PANACOR PPP vitreous enamelled panels have very high reflectivity that remains unchanged over time. The vitrified surface resists discolouration and loss of brightness, contributing to significant energy savings by optimising tunnel lighting systems and reducing operational costs. - NON-COMBUSTIBLE:

Vitreous enamelled steel is incombustible, will neither ignite nor burn, and can endure extreme temperatures up to +400°C. PANACOR PPP architectural panels offer a minimum fire resistance rating of two hours, depending on their design and the backing materials used, and due to their inorganic nature, they also do not emit toxic gases when exposed to fire. - HIGH DURABILITY:

PANACOR PPP panels offer exceptional durability, with a vitreous enamel coating that is resistant to scratches, graffiti, and impact. This makes them perfectly suited for high-traffic areas and environments subject to heavy wear and tear. - INFRASTRUCTURE:

PANACOR PPP is non-combustible and virtually indestructible, positioning them as one of the most durable cladding products available for infrastructure projects. - VERSATILE:

PANACOR PPP Panels can be custom-designed into a wide range of shapes and sizes, and are also available in perforated or curved formats for specific applications, offering architects and designers a highly versatile solution.

The unique performance of vitreous enamel results in a versatility that enables custom designs of all shapes and sizes, such as columns, doors, benches, and specific shapes for all kinds of architectural purposes. - PAINT SYSTEM:

PANACOR PPP Vitreous enamelled panels offer long-lasting protection against corrosion and are fully resistant to premature ageing caused by ultraviolet light exposure. Their original colours and surface finish remain intact even under continuous exposure to sunlight, rainforest, and other environmental conditions, which makes them ideal for either interior or exterior applications. - APPEARANCE AND HYGIENE:

PANACOR PPP Vitreous enamelled steel panels are sterile, germ-free, odourless, and easy to clean. Combined with its other characteristics and a smooth colour-fast surface, it provides an unmatched visually aesthetic appearance.

PANACOR PPP features a non-porous, non-stick surface that does not harbour bacteria, allowing for deep cleaning using hospital-grade disinfectants without compromising the finish. - ENVIRONMENTALLY FRIENDLY AND RECYCLEABLE:

PANACOR PPP is manufactured using environmentally friendly processes, free from harmful substances and without posing risks to the people or the environment. The enamelled panels are fully recyclable and can be safely reintroduced into waste recycling without polluting the environment. - DIRT-REPELLENT AND GRAFFITI-PROOF:

PANACOR PPP does not retain wind-borne particles or brake dust, thanks to its ultra-smooth, glass-like enamel surface. Adhesives, graffiti, and other chemical residues can be easily cleaned off, maintaining the panel’s pristine appearance with minimal effort.

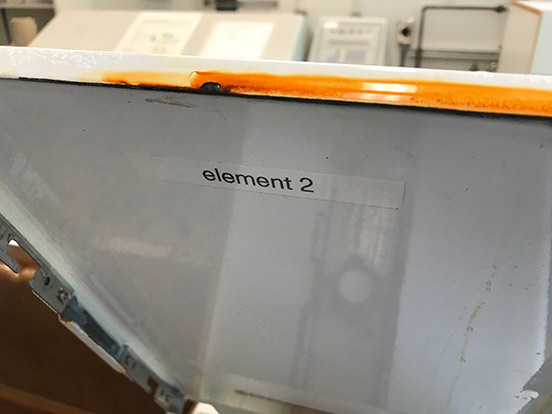

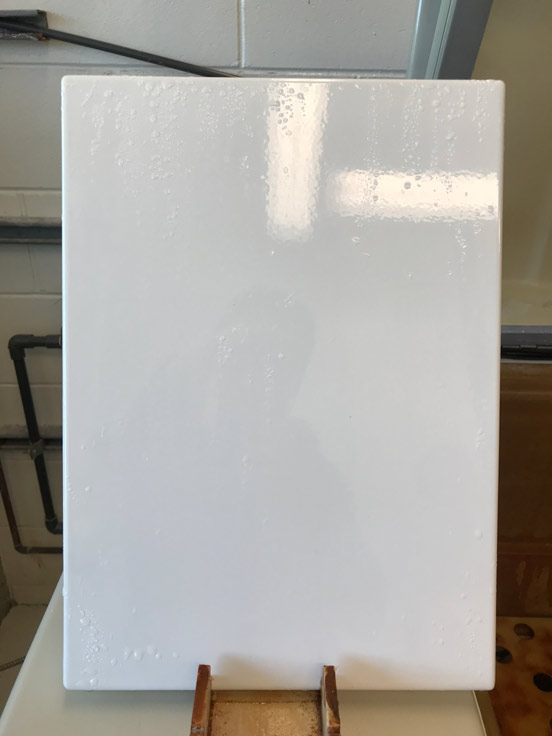

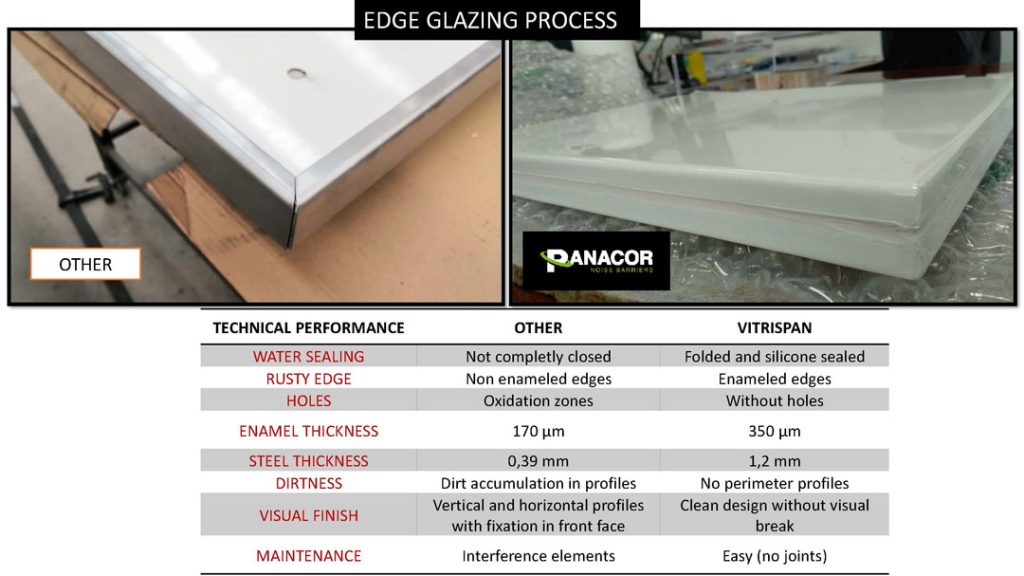

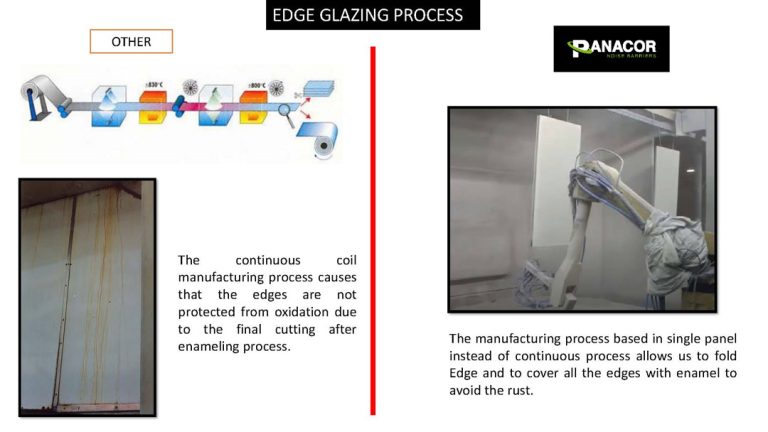

To ensure maximum durability, it is essential to prevent the accumulation of moisture and dirt, as there are key factors that accelerate corrosion. With longevity in mind, we have developed multiple panel models specifically designed to enhance durability beyond 50 years. These models have undergone rigorous testing in saline chamber environments for up to 1000 hours to validate their long-term performance.

Standard panels: Corrosion on steel sheets cut edges after 250 hours

PANACOR PPP: Steel sheet after 1000 hours

Maintenance-Friendly Design

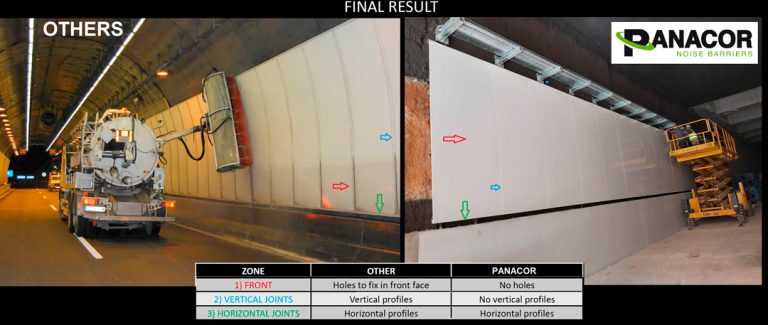

Our panel design conceals all cut steel sheet edges within the panel itself to effectively prevent corrosion. Additionally, by eliminating horizontal and vertical joints where dirt and moisture typically accumulate, the risk of early corrosion is significantly reduced. This streamlined design not only enhances durability but also simplifies maintenance, making routine cleaning much easier.

Standard panels that rely on additional U-profiles to seal the edges and extra fixing profiles to attach them to the wall tend to trap dirt and moisture. These elements create hard-to-clean areas that increase the risk of corrosion over time.

Vertical and horizontal joints cleaning

Cleaning the panels with a truck-mounted system is challenging, as the joints are not easily accessible and tend to retain dirt.

- PREPARATORY WORK

The first stage of every project begins with detailed design, engineering calculations, and the development of both 2D and 3D models. Based on the specific project requirements, we tailor the panel design to meet all functional and structural needs.

We also perform structural calculations for the supporting metallic framework using Computational Fluid Dynamics (CFD) analysis. This ensures the design accounts for aerodynamic loads generated by vehicles passing near the panels, guaranteeing long-term stability and performance.

- STEEL CUTTING AND SHAPING

Our panels are formed from high-quality cold-rolled steel sheets, shaped precisely according to the dimensions and specifications outlined in the approved technical drawings. These designs are carefully reviewed by our engineering team to ensure optimal performance and durability.

All cutting and forming processes are carried out in-house at our factory, eliminating the need for any on-site modifications. By completing the panel shaping before the vitrification process, we ensure that both faces of the steel are fully protected by a uniform vitreous enamel coating, offering maximum resistance to corrosion and wear.

- VITRIFICATION

The vitrification process is carried out in full compliance with the UNE-EN 14431 standard, ensuring consistent quality and performance. The enamels used are formulated from frits milled in water together with clay, coloring pigments, and other materials to achieve a smooth, cream-like consistency known as “slip.”

This slip is wet-sprayed directly onto the steel panels using specialized robotic systems for uniform coverage and precision. The vitreous enamel system consists of two layers: a ground coat applied to all sides of the panel, and a top coat that provides the final color and finish.

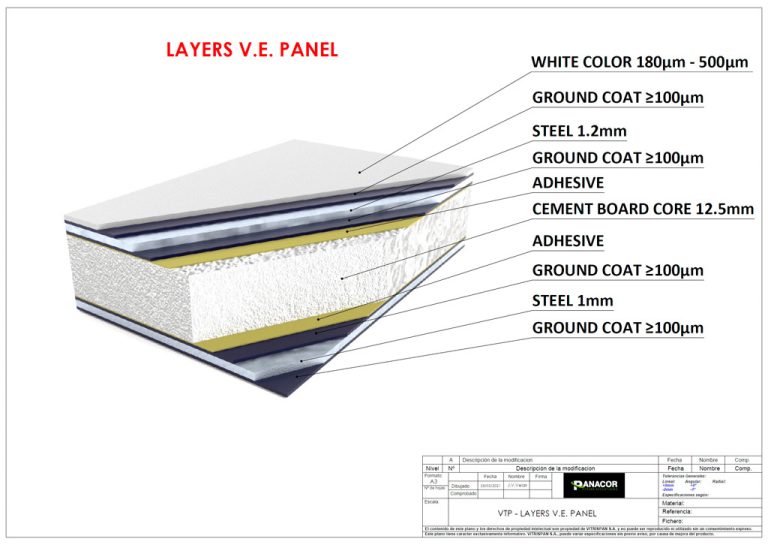

After each layer is applied, the panels are fired in an industrial oven at temperatures exceeding 800°C, where the enamel vitrifies and fuses permanently to the steel surface. This process results in a highly durable, corrosion-resistant finish, with a coating thickness ranging between 185µ and 500µ on the front side, and a minimum of 100µ on the other side.

Steel sheets going into the oven at 800°C

- Backing

Most architectural panels coated with vitreous enamel are laminated with backing materials to enhance performance and ensure optimal flatness. These backings are used for a variety of purposes, including improving acoustic performance, providing fire resistance and thermal insulation, and adding structural rigidity to maintain dimensional stability.

The following are the most widely used types of vitreous enamel panel backings:

- Fireproof and waterproof timber backing

- Calcium Silicate board backing

- Hexagonal Cell Phenolic “Honeycomb” backing

- Hexagonal Cell Aluminum “Honeycomb” backing

- Fibreglass backing

- Terophon backing (acoustic material)

Quality control ensures that each product meets its specified parameters and performance standards. Once approved, the panels are carefully packaged and prepared for dispatch. They are packed in suitable crates, making them secure for both air and sea freight, with all loading operations conducted in a sheltered truck and container loading area to protect the product from environmental exposure.

Panels stocked and ready for packaging

Palets ready to dispatch

The panels are securely loaded into containers, with protective measures in place to ensure stability and prevent damage during transportation.

The exceptional toughness and long-lasting color stability of PANACOR PPP, combined with its superior sound absorption properties, make it one of the most durable cladding solutions available on the market. These attributes have made it a preferred choice for demanding infrastructure applications, including tunnel linings and airports..

Key Advantages of PANACOR PPP in Infrastructure Projects Include:

- PANACOR PPP remains unaffected in both appearance and performance, even under prolonged exposure to UV rays and extreme weather conditions.

- PANACOR PPP steel features exceptional hardness and high surface lubricity, making it highly resistant to scratches and impacts, perfect for high-traffic pedestrian areas.

- PANACOR PPP offers high resistance to most acids and alkalis, as well as excellent durability against sea spray, making it an ideal choice for coastal and marine environments.

- PANACOR PPP is also graffiti-resistant; the nature of the panel enables the complete removal of paint.

- Testing has proven that it is non-combustible.

Graffiti cleaning

TUNNELS CLADDING APPLICATIONS:

The design of road tunnels must address multiple technical and economic factors, all aimed at ensuring maximum safety. PANACOR PPP vitrified enamel panels offer a range of benefits that make them an ideal solution for tunnel cladding.

Beyond their aesthetic appeal, one of the key advantages of PANACOR PPP panels lies in their photometric properties, specifically their optimized color and reflectivity. These features lead to significant energy savings in tunnel lighting systems and, more importantly, enhance visibility and safety for drivers, resulting in a more comfortable driving experience.

A common issue in tunnel environments is the poor illumination of concrete walls. Ideally, wall lighting should match the brightness of the road surface. However, concrete walls tend to absorb dust, cinders, and vehicle emissions, causing their naturally dull surface to darken even further, which reduces visibility and increases the risk.

Using vitrified enamel panels for tunnel cladding significantly enhances visual guidance and contrast, aiding driver navigation and reducing the risk of accidents. This improved visibility supports compliance with European safety regulations for tunnel infrastructure.

PANACOR PPP panels offer superior performance thanks to their exceptional impact resistance and dimensional stability under extreme temperatures, ensuring long-term safety and reliability. Compared to other cladding systems, such as thin-gauge metal panels or thermoplastic coatings, PANACOR PPP panels provide greater structural integrity and a longer lifespan.

In addition, the vitrified enamel surface is highly resistant to corrosion and chemical attack, particularly from acidic gases produced by vehicle emissions. This makes PANACOR PPP an ideal solution for tunnel environments, where exposure to aggressive atmospheric conditions is constant.

The exceptional qualities of enamel cladding make it an ideal choice for road tunnel applications, offering unmatched durability, extended service life, and minimal maintenance requirements.

These are the main advantages of this kind of application:

- No fire load: Offers protection against fire and impact, shielding the tunnel walls effectively.

- High reflectivity: Glossy surfaces enhance brightness, reduce tunnel-related anxiety, and contribute to energy savings.

- Low maintenance: Panels are exceptionally easy to clean, reducing the need for water, detergents, and labor.

- Quick replacement: Damaged panels can be swiftly replaced without interrupting tunnel operations.

- Extended lifespan: Designed to last for at least 30 years.

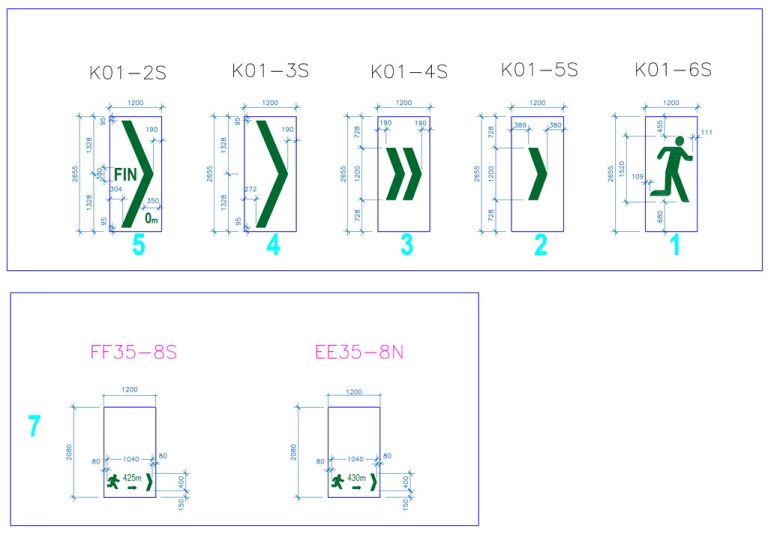

- Integrated signage: Enamelled panels can include durable information signs that remain visible for the entire service life.

- Infrastructure protection: Shields internal tunnel systems such as conduits, cables, and pipes.

- Water management: The specially engineered enamelled reverse side can help redirect runoff from surrounding mountains.

One of the key advantages of enamel is its ability to support high-quality, long-lasting printing. Whether for route maps, information signs, or full-colour imagery, enamel preserves both detail and vibrancy over time. Using advanced 4-colour process printing, more than 10 colours can be applied with exceptional clarity, maintaining brilliance even after years of exposure. Prints can be produced in sizes up to 1250 x 2500 mm, making enamel an ideal medium for combining function with visual impact.

We handle the complete process, from design to implementation, ensuring seamless coordination across all project phases.

Our scope includes the design and structural calculations of the metallic support system and vitreous enamel steel panels, specifically engineered to withstand aerodynamic pressures caused by passing vehicles.

The resulting substructure and panel assembly form a stable, dynamically tested system built for durability and long-term performance.

Our unwavering dedication to fulfilling our clients’ and customers’ expectations is demonstrated through a comprehensive quality control system that begins at the specification stage and continues through to the delivery of guaranteed products.

All processes are conducted with a focus on:

- Operating within the ISO 9000 Quality Standards framework to ensure the reliability of our systems.

- Delivering products and services that consistently meet the highest quality benchmarks.

- Driving continuous product improvement through the implementation of the finest quality practices.

Our products are manufactured in full compliance with EN ISO 28722:2011, “Vitreous and porcelain enamels: Characteristics of enamel coatings applied to steel panels intended for architecture”.

All PANACOR PPP panels are custom-manufactured to meet project-specific dimensions. While the standard size typically ranges up to 2400 x 1200 mm, larger panels may become excessively heavy. The maximum size available is 3000 x 1500 mm.

PANACOR panels are produced in heavy-gauge steel, with a thickness exceeding 1.2 mm, in full compliance with UNE‐EN 14431 standards. Both sides of the steel are fully protected with a vitreous enamel coating, ensuring durability, resistance, and long-term performance. The steel core also offers superior strength and sag resistance during both the enameling process and the panel’s lifecycle.

To further optimize weight without compromising structural integrity, panel cores can be manufactured using fiber cement board or aluminum honeycomb materials.

We offer complete flexibility in color selection; any RAL color can be applied as the final finish. To ensure precise color matching, we conduct a series of tests and adjustments until the desired shade is accurately achieved.

Samples painted on a panel for color selection

Raw material for color creation